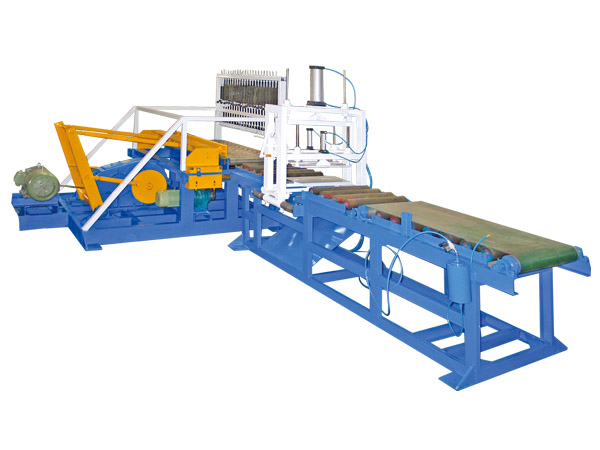

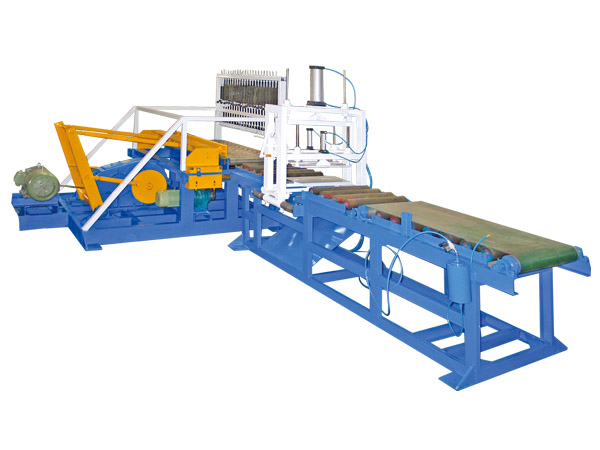

The GDQP dual strip photoelectric cutting system is used for hard plastic shaping and cutting of coal gangue and shale. During the production process, photoelectric detection is used to ensure that the double cut blocks are smooth and free of mud heads. The product runs smoothly and has a low failure rate. Equipped with a fully automatic billet coding system, PLC programming and unified control of

The GDQP dual strip photoelectric cutting system is used for hard plastic shaping and cutting of coal gangue and shale. During the production process, photoelectric detection is used to ensure that the double cut blocks are smooth and free of mud heads. The product runs smoothly and has a low failure rate. Equipped with a fully automatic billet coding system, PLC programming and unified control of touch commands, with fault prompt and alarm functions to achieve automation of the working process.