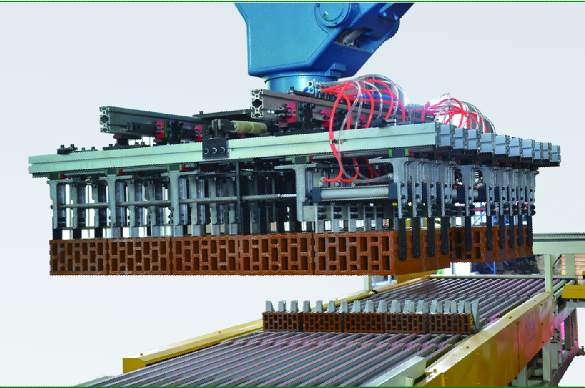

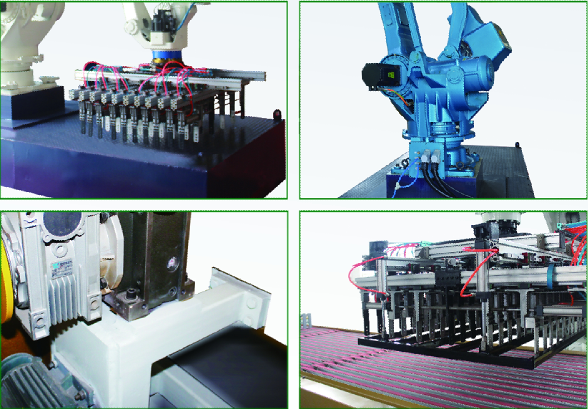

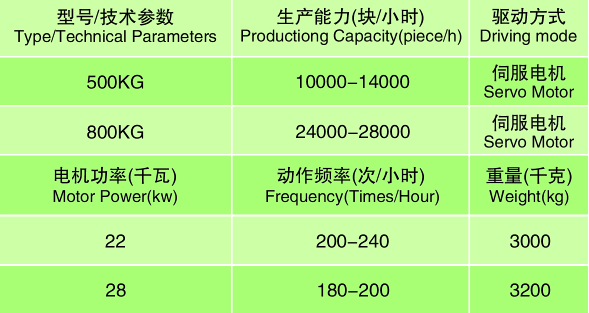

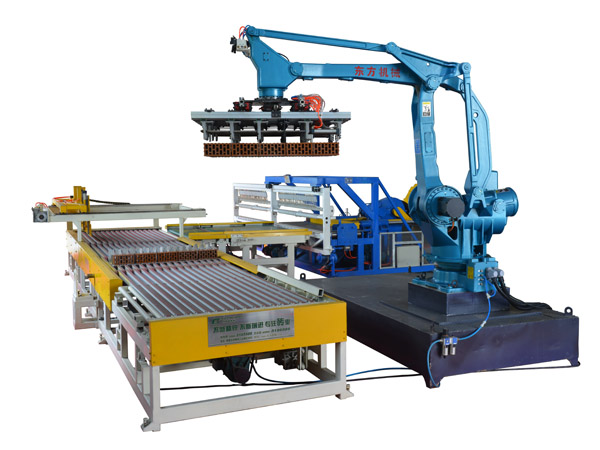

The robot barcode system consists of a robot, servo motor system, clamp system, billet transportation system, billet flipping system, billet storage system, grouping system, power distribution, and gas and electricity systems. It is a molding and palletizing machine suitable for large masonry block bricks, rectangular bricks, high porosity hollow bricks and other varieties, and can achieve the dou

3. Low loss rate, easy operation, and low failure rate