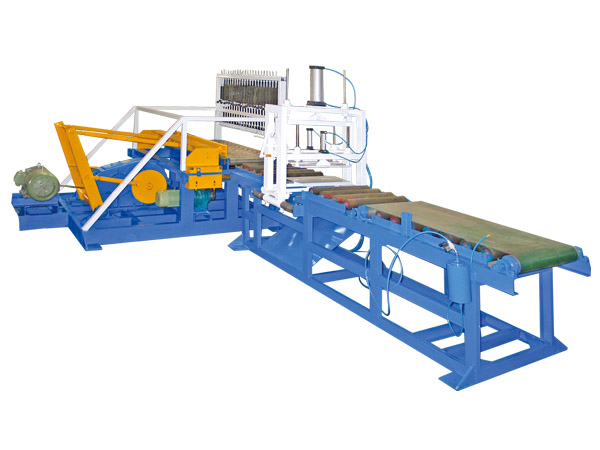

The GDQP dual strip photoelectric cutting system is used for hard plastic shaping and cutting of coal gangue and shale. During the production process, photoelectric detection is used to ensure that the double cut blocks are smooth and free of mud heads. The product runs smoothly and has a low failure rate. Equipped with a fully automatic billet coding system, PLC programming and unified control of

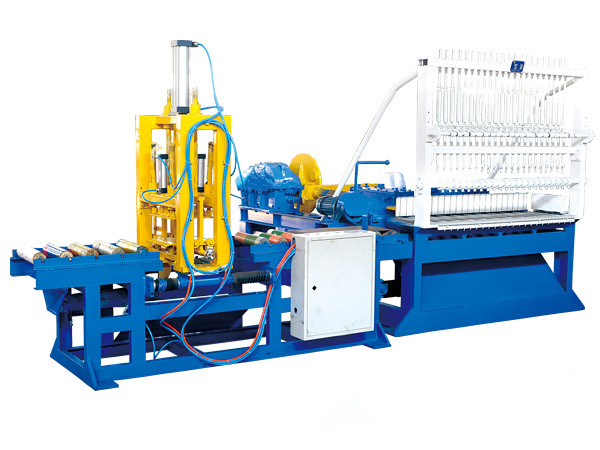

The pneumatic billet and strip cutting system is equipped with photoelectric detection, computer automatic control, and continuous uninterrupted operation to effectively increase production. It adopts stainless steel roller panels, fully achieving energy-saving effects. Optoelectronic detection during operation, with fault prompt and alarm functions, achieving automation of the working process.

SJ dual axis strong mixer, with the mixing spindle made of Hanggang 40 chromium steel, which can effectively prevent shaft breakage and bending; Bearings used: Wafangdian ZWZ, Harbin HRB, Luoyang LYC, Japan NTN; Gear quenching heat treatment, with a hardness of up to HRC50; The bearing seat is made of cast steel; The stirring blade is made of cast steel, which can effectively wear resistance; The

The pneumatic multi mud strip cutting machine is controlled by PLC programming, with the cylinder as the cutting power and equipped with a mud strip positioning device. Accurate positioning, cross cutting technology for cutting mud strips without tilting, complete without mud heads, suitable for cutting semi hard plastic and hard plastic mud strips made from shale and coal grinding stone as raw ma